HOW TO PREVENT THREAD JAMS.

This page will help you prevent thread jams as you begin to sew. Some machines (oscillators) are more likely to jam than are others (full rotary). The following steps can help prevent this problem and get you off to a good start.

… Make sure your machine is properly threaded. Pay particular attention to tension disc and check spring.

… Make sure thread take-up lever is at its highest position when you begin to sew. This puts the machine in the first phase of the stitch formation and also completes the previous stitch. Note just because the needle is up and out of the fabric it does not mean the stitch cycle is complete, you must have the take-up lever to its highest position.

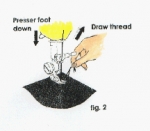

… Start with aproximately 3" to 4" of top and bottom thread held to the back and side. Position needle into the fabric area approximately 1/2" from the edge of the fabric (make sure the pressure foot has been lowered), give a slight draw to both threads as you start to sew. After 3 to 5 stitches let the threads go and use reverse if appropriate for your project. Note if you use this method; drawing threads while you actually start to sew; you can start sewing right on the edge of the fabric which is advantageous when working with small pieces of fabric such as small quilt pieces.

If you experience thread jams while you are sewing you most likely have a mechanical problem, maybe time to visit your local professional sewing machine technician.

| Weight | 0.00000000 kg |

|---|---|

| Dimensions | 0.00000000 × 0.00000000 × 0.00000000 cm |